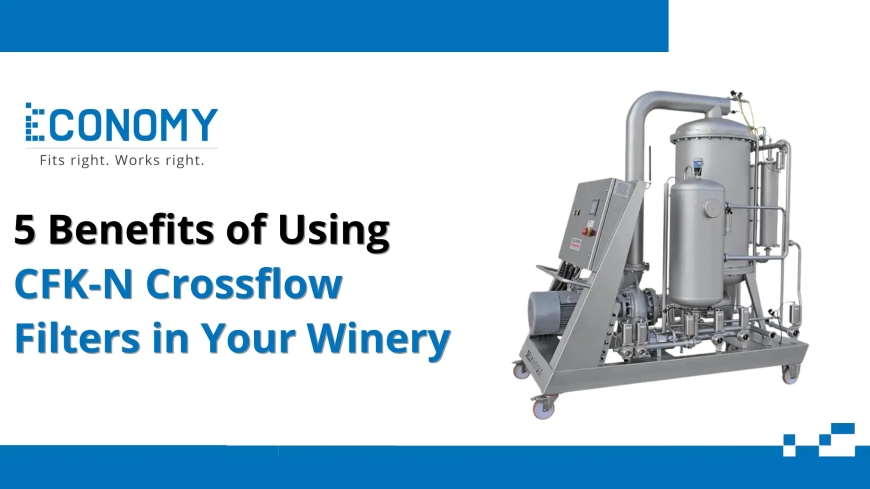

5 Benefits of Using CFK-N Cross Flow Filters in Your Winery

CFK-N crossflow filters offer wineries a smart, sustainable, and high-performance solution for modern wine production.

What Are CFK-N Crossflow Filters?

CFK-N crossflow filters are high-performance filtration systems designed specifically for the wine and beverage industry. These filters operate using crossflowor tangential flowfiltration, where the liquid flows parallel to the filter membrane. This allows clean wine to pass through while suspended solids like yeast, bacteria, and fine particulates are retained. Unlike traditional filtration systems that rely on gravity or disposable filter media, CFK-N filters offer a closed, automated, and highly efficient solution to wine clarification and stabilization.

Features That Make CFK-N Filters Unique

CFK-N filters stand out in the market thanks to their advanced engineering and winery-focused features:

-

Food-grade polymer membranes that ensure selective retention without compromising flavor.

-

Automated control systems with touchscreen interfaces and programmable logic controllers (PLC).

-

Energy-efficient operation that reduces power consumption and operating costs.

-

Compact modular design that saves space and scales easily with production.

-

CIP (clean-in-place) functionality that automates cleaning, reducing labor and downtime.

These features collectively make CFK-N filters ideal for modern wineries focused on consistency, efficiency, and product quality.

The Benefits of CFK-N Crossflow Filters

1. Superior Wine Quality

CFK-N filters deliver gentle filtration that protects a wines aromatic and flavor profile. Since the wine never passes through harsh filter media, there's minimal oxygen exposure and thermal stress. This ensures that the final product retains its intended characteristicsfrom aroma to mouthfeel.

2. Reduced Product Loss

With traditional filtration, wine loss can occur due to retained volume in filter pads or filter aids. CFK-N filters minimize product loss by efficiently separating solids without absorbing or trapping liquid. This means higher yield and more bottles per batch.

3. Lower Operating Costs

Though the initial cost may be higher, CFK-N filters are cost-effective in the long run. Their energy-efficient design, minimal use of consumables, and low maintenance requirements result in significant savings. Labor costs are also reduced due to the fully automated process.

4. Eco-Friendly and Sustainable

By eliminating the need for disposable filtration aids (like diatomaceous earth), CFK-N filters reduce waste and environmental impact. They also use less water and fewer chemicals during cleaning cycles, supporting sustainable winemaking practices.

5. Versatile and Scalable

Whether you're filtering white, red, ros, or even sparkling wines, CFK-N filters adapt easily. Their modular systems allow for capacity expansion as production grows, making them suitable for boutique wineries and large-scale operations alike.

Top Advantages of CFK-N Crossflow Filters

-

No use of filter aids or pads reduces waste and handling risks.

-

High filtration accuracy removes particles down to 0.2 microns.

-

Longer filtration cycles uninterrupted operation boosts efficiency.

-

Fully enclosed process hygienic and contamination-free.

-

Minimal supervision required ideal for small teams or high-volume production.

How to Choose the Right Crossflow Filter for Your Winery

The ideal crossflow filter depends on your winerys size, output, and production goals. Important considerations include:

-

Filtration capacity (L/hr or HL/hr)

-

Membrane pore size for clarity requirements

-

Wine types (white, red, sparkling)

-

Automation level manual vs. fully automatic

-

Footprint available space for installation

-

Expandability modular systems for future scaling

Selecting the Best Crossflow Filtration Equipment

When evaluating equipment, prioritize:

-

Ease of maintenance and cleaning

-

Reputation of the manufacturer

-

After-sales support and spare parts availability

-

Warranty and service contracts

-

Track record in similar wineries

CFK-N systems are built with these concerns in mind, offering plug-and-play installation, minimal maintenance, and robust support.

Why CFK-N Filters Are a Preferred Choice

Wineries worldwide trust CFK-N filters because they combine performance, reliability, and cost savings. Their ability to handle different wine types, ease of operation, and long-term return on investment make them a smart choice. Whether you're producing 10,000 bottles or 1 million, the system can be tailored to fit your needs.

Crossflow Filtration: Advantages and Disadvantages

Advantages:

-

Consistent output clarity throughout the process

-

Long membrane life with proper cleaning

-

Safe for operators due to closed design

-

No need for pre-filtration or additives

-

Saves time and resources through automation

Disadvantages:

-

Higher initial investment than traditional filters

-

Requires operator training for best performance

-

Not suitable for unclarified must without pre-treatment

Despite these drawbacks, the benefits of long-term use and high efficiency often outweigh the limitations.

Real-World Applications of CFK-N Crossflow Filters

Numerous wineries have reported improved quality and efficiency after adopting CFK-N systems. For example, a vineyard in California reported a 25% increase in product yield and 40% reduction in labor hours post-installation. A French organic winery praised its low water usage and simple integration into their sustainable production line. These success stories demonstrate the tangible benefits of adopting this advanced filtration technology.

Case Studies: Success Stories in Wineries

-

Case Study 1: Boutique Winery in South Africa

A small winery processing around 80,000 liters annually replaced their pad filter with a CFK-N unit. The results included better flavor retention, reduced bottling delays, and zero filter pad waste. -

Case Study 2: Mid-Sized Winery in Australia

After upgrading to CFK-N, the winery achieved 30% faster turnaround times and reported cleaner, brighter wines without any post-filtration corrections.

Conclusion

CFK-N crossflow filters offer wineries a smart, sustainable, and high-performance solution for modern wine production. With benefits including superior clarity, product yield, reduced waste, and consistent quality, these systems represent the future of winery filtration. Whether you're aiming to elevate wine quality or scale up operations, investing in a CFK-N crossflow filter is a decision that brings both immediate and long-term rewards.