What Is a Bespoke EOL Tester? Custom Solutions for Manufacturing

Discover what a bespoke EOL tester is and how custom solutions improve quality, efficiency, and compliance in manufacturing processes.

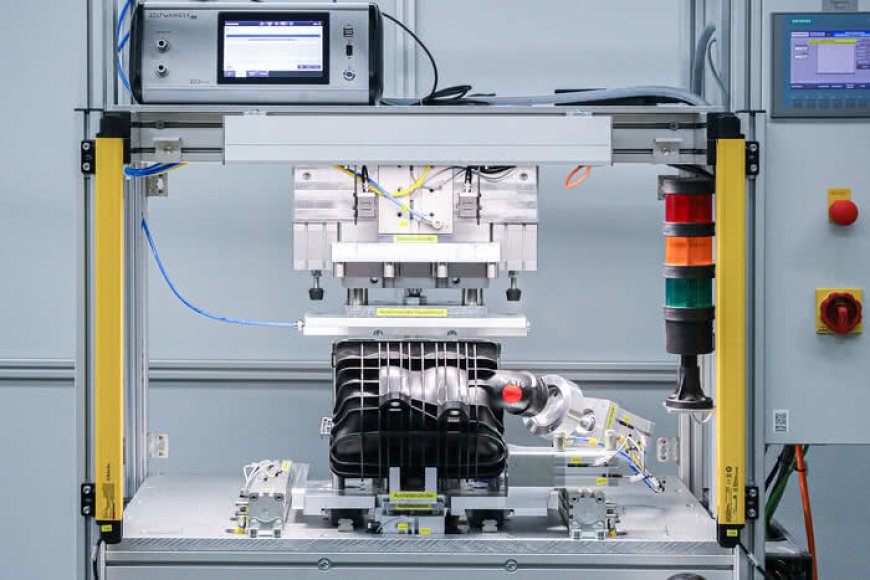

Ever wondered what happens to a product just before it rolls off the assembly line? Thats where a bespoke EOL tester steps in. Simply put, its a custom end-of-line testing system designed to check products meet specified criteriabe it electronics, machinery, or aerospace components. These tailored solutions ensure every part that leaves the factory is top-quality and defect-free. Learn more about Bespoke Eol Tester systems tailored for todays complex manufacturing.

Why Tailored Testing Beats Off-the-Shelf Systems

Generic EOL testers can only cover basic checks. But manufacturing isnt always basic. Bespoke systems are designed around your exact product specs, workflow, and quality standards. That means higher accuracy, better throughput, and fewer false failsand that leads to happier customers.

Key Features of a Bespoke EOL Tester

Custom EOL testers normally include:

-

Tailored interfaces for unique product designs

-

Specialized sensors or probes for complex systems

-

Automated pass/fail data logging and reporting

-

Modular test stations that flex with production volume

-

Integration with MES or ERP systems for full traceability

Industries That Benefit Most

Beside consumer electronics, bespoke EOL testers make a big difference in:

-

Automotive: engine control units, wiring harnesses

-

Aerospace: avionics, hydraulics, safety components

-

Medical Devices: sterilization cycles, sensor accuracy

-

Industrial Machines: motors, valves, safety interlocks

By designing for your specific product, you catch issues that standard testers might miss.

How Bespoke EOL Testers Boost Quality

With a custom tester, you decide what quality means. You define test cycles, thresholds, and acceptance criteria. That means each product is validated to your exact needs, not generic benchmarks. When defects travel far, the right check at the end can save moneyand your reputation.

Cost vs. Value in Custom Testing

Sure, bespoke systems cost more up front than a plug-and-play tester. But they pay you back in reduced recalls, faster throughput, and fewer returns. For high-volume or regulated industries, the ROI is often clear within months.

Designing a Bespoke EOL Tester System

Creating one isnt guesswork. Heres how it usually works:

-

Discovery Phase

We visit your facility, interview engineers, and map out your product flow. -

Requirement Definition

We document test needs: electrical, mechanical, software, tolerances. -

Concept & Prototype

We build a sample cell to simulate how it works on your line. -

Validation

We run sample products to confirm test accuracy and cycle time. -

Deployment

You get full operator training, documentation, and support plans. -

Evolution

As your product or volume changes, the tester can grow too.

Regulatory and Compliance Assurance

In aerospace, medical, or automotive, compliance is non-negotiable. Bespoke testers can be designed to support ISO 9001, ISO 13485, AS9100, or IATF 16949 standards. Plus, custom testers track data for audits and traceability, reducing compliance headaches.

Smart Features to Include

Many bespoke EOL testers now come with:

-

Cloud-based data storage and analysis

-

AI-driven anomaly detection

-

Real-time dashboards and alerts

-

Remote support and software updates

These smart' elements take testing into the 21st-century and keep you ahead of the curve.

Maintenance and Lifecycle Support

The best bespoke testers come with warranties, spare parts, and service-level agreements. When production never sleeps, support that never stops is critical. Regular calibration ensures accuracy and prevents downtime.

Choosing the Right Partner

Partnering with the right vendor means choosing someone who understands your industry and product demands. Look for tech companies with:

-

Proven track record in your sector

-

In-house design, electronics, and software teams

-

Strong user training and documentation

-

Certification to relevant quality systems

A partner like Bespoke Eol Tester specialists at Expert Technologies brings both technical depth and hands-on support.

Table: ? Key Benefits of Bespoke EOL Testers

| Benefit | Why It Matters |

|---|---|

| Precision Testing | Customized checks reduces false failures |

| Enhanced Data Capture | Supports traceability, AI insights, and compliance reporting |

| Scalability | Modular systems grow with your output |

| Regulatory Alignment | Meets ISO, AS, or FDA standards easily |

| Cost Efficiency Over Time | Savings from fewer defects and increased throughput |

Real Work Example

One electronics OEM needed to test high-voltage modules for insulation and current leakage. Generic testers couldn't handle unit-to-unit variation, so they commissioned a bespoke tester with 10 automated probe heads. Result? Defective parts caught instantly, production doubled, and calibration records were audit-readywithin six months, ROI was achieved.

Conclusion: Why You Should Consider One

If youre producing products at scaleespecially in a regulated sectora bespoke EOL tester isnt just helpful, its essential. It aligns testing with your exact needs, boosts quality, lowers costs, and ensures compliance. And when you pick the right partner, its an investment that accelerates your manufacturing capabilities.